- +91 9822402110 / +91 9370060000

- info@safensecure.co.in

- Ceritified ( ISO 9001-2015 )

Medium Velocity Water Spray System in Pune

Medium Velocity Water Spray System in Pune

There are two types of Water Spray System Medium Velocity Water Spray System in Pune and High Velocity Water Spray System in Pune

High velocity systems are often used to protect equipment that incorporate heavy or medium oils equipment such as transformers, circuit breakers, diesel engines and fuel oil storage tanks, turbo alternator lube oil systems and oil fired boilers. The high velocity nozzles are specifically designed to discharge a jet of water at high speed.

In this type of Water Spray System in Pune the water jet forms a cone of coarse spray of uniform density which is discharged over a defined area. The coarse spray is able to penetrate the flame zone and reach the surface of the burning oil. The turbulence created by the high velocity spray forms an oil-in-water emulsion on the surface of the oil that will not burn. This “emulsification” is the principal way the fire is extinguished, along with a cooling and smothering effect. The shape of the spray cone, the fire area contacted and the water flow is all controlled by the nozzle specifications – the orifice size and the shape of the internal swirl plate – along with the water pressure and the orientation of the nozzle.

In Medium Velocity Water Spray System in Pune medium velocity sprayers discharge a water spray of finely divided droplets at medium velocity. They are ideal for protecting hazards involving light oils where emulsification from high velocity sprayers is not possible.

The fine spray has a high heat absorption rate so Medium Velocity Water Spray System in Pune is an effective method of protecting adjacent plant and structures from heat during a fire by providing a continuous cooling spray over the exposed surfaces.

Keeping nearby equipment cool minimizes damage and reduces the risk of explosion. Medium Velocity Water Spray System in Pune can be used in combination with other fire fighting systems – dry chemical and foam can be used effectively under the discharge. The fine spray also works to dilute and disperse flammable vapors.

The sprayers use an external deflector to achieve the desired discharge angle and spray characteristics. Wormald engineers will select the correct sprayers with flow rate, discharge angle and droplet size to best suit your application. Medium Velocity Water Spray System in Pune use water economically and so can be used for long periods if required.

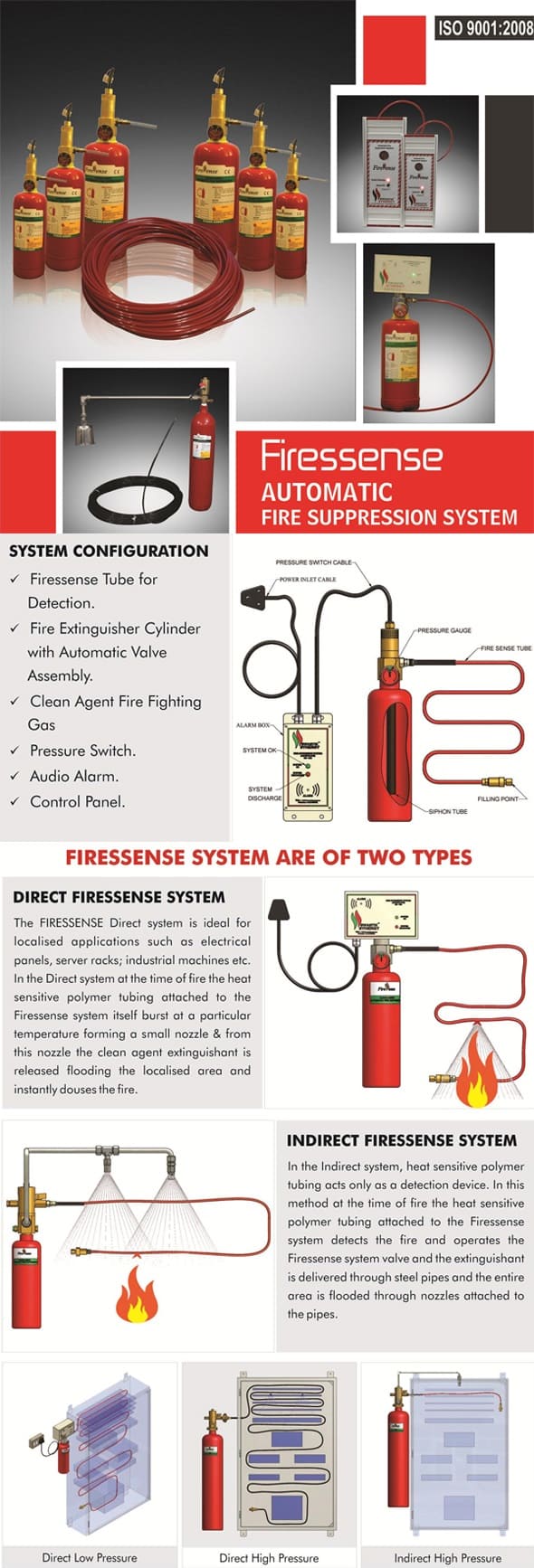

Medium Velocity Water Spray System in Pune is intended to prevent or extinguish fires automatically within seconds, where there is electrical or sensitive electronic equipment serving a critical operation, the loss of which would not only be the value of the equipment but also the cost of business interruption such as caused by damage to Server Room, Data storage room.

Safe ‘N’ Secure specializes in the design, installation, testing, commissioning & service of fixed fire fighting systems.

Argonite has been developed to meet the demands from the industry for an environmentally friendly media. Argonite is non-toxic, non-corrosive, non-fogging and leaves no residue. Argonite meets the challenge from both the Montreal- and Kyoto protocol with no ozone depletion potential or global warming potential.

Argonite is tested and approved by regulatory bodies throughout the world, and is effective against fires in almost all combustible materials and flammable liquids.

Applications

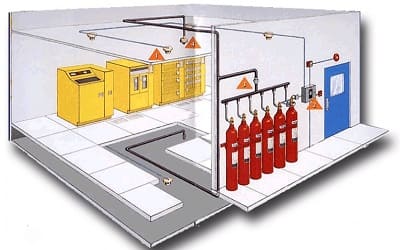

Argonite systems are ideally suited to the protection of fixed equipment and plant. They are particularly applicable for high value risks where fi res can have devastating consequences way beyond the cost of damage and lost production.

System design

In a closed space, almost all fires are extinguished in less than 60 seconds when the oxygen concentration falls below 15%. The Argonite fire extinguishing system, based on a mixture of 50% Argon and 50% Nitrogen, reduces the oxygen concentration to a level acceptable to human exposure over short periods – thus eliminating the fire quickly and effectively without affecting personnel.

Knowing the size and complexity of the area to be protected, the fire hazard present and the requirements of the local approving authority, a dedicated computer programme is used to specify the size and geometry of the Argonite system hardware.

In response to the impending production phase out of Halon fire extinguishants, FM-200 ( Heptafluoropropane ) is a replacement for Halon 1301 in applications requiring a clean environmentally acceptable fire extinguishing agent, suitable for use in manned areas. It is a colourless gas at standard conditions, exhibiting a boiling point of -16.4 Degree Centigrade. Through the use of properly designed equipment, FM-200 will mix well in a protected enclosure to provide a homogenous mixture in air. For fire suppression applications, FM-200 is super pressurized to achieve rapid discharge into the protected environment.

| Technical Specification | FM-200 |

| Chemical Formula | C3F7H |

| Ozone Depletion Potential | 0 |

| Molecular Weight | 170.03 |

| Boiling Point | -16.4 Degree Cent |

| Critical Temperature | 102 Degree Cent |

| Extinguishing Concentration ,Heptane Cup | 5.8 % |

| Burner ( %by Volume ) | |

| Vapour Pressure at 21 Degree C | 68.8 psia |

FM-200 works by physical action, the molecules absorb heat so that the temperature of the flame falls to a point below which it cannot propagate, and the fire is extinguished. The oxygen depleting effect is minimal as only small quantities of the gas are used.

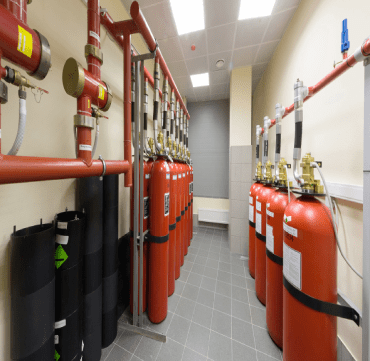

Carbon dioxide (CO2) gas has been used as an extinguishing agent in fixed installations since the beginning of the twentieth century. NFPA-12 ( National Fire Protection Association ) Rules and BIS 6382 codes for design of such system are used as standards for CO2 extinguishing systems. These fire extinguishing installations are usually provided on premises where water and foam cannot be used. CO2 can be stored in high pressure seamless steel cylinders in liquid form with maximum filling ratio of 0.667 kg/liter of cylinder volume.At atmospheric pressure and 21 Degree Cel. Temperature, 1kg of liquid CO2 vaporizes to occupy 560 liters. This means that in order to “ flood/inject” CO2 gas into an environment, causing volumetric reduction of oxygen gas concentration, a large quantity of CO2 gas can be effectively stored in liquid form in relatively small cylinder volume.

HOW THE CO2 HIGH PRESSURE SYSTEM WORKS

- The high pressure system operates on efficient pneumatic principles.

- Pneumatic pressure is used to open the valves and operate pressure switches, etc.

- No wires, pulley, equalizers or falling weights are used in this system. Operating parts are located internally, eliminating the need for bulky protective cages.

- The typical system offers three independent means of actuation : (1) Automatic (2) Remote Manual (3) Direct Manual.

Because its use concentration is much lower than its No Observable Adverse Effects Level (NOAEL), FK-5-1-12/ FK 5112/ NOVEC 1230 fluid offers the widest margin of safety of any viable halon replacement available on the market today.

| 3M™ Novec™ 1230 Fire Protection Fluid Safety Margin | ||||

|---|---|---|---|---|

| Agent | FK-5-1-12/ FK 5112/ NOVEC 1230 | Halon 1301 | HFC-125 | HFC-227ea |

| Use Concentration | 4-6% | 5% | 8.7-12.1% | 7.5-8.7% |

| NOAEL3 | 10%4 | 5% | 7.5% | 9% |

| Safety Margin | 67-150% | Nil | Nil | 3-20% |

One fire protection fluid. So many reasons to use it.

Here is the new standard for halon replacement. FK-5-1-12/ FK 5112/ NOVEC 1230 fluid offers a long-term, sustainable technology that has the greatest margin of safety, the lowest GWP for halocarbon alternatives, and zero ozone depletion potential.

What is FK-5-1-12/ FK 5112/ NOVEC 1230 fluid ?

FK-5-1-12/ FK 5112/ NOVEC 1230 fluid is a fluoroketone — a proprietary 3M technology that offers a number of important advantages over conventional halon replacements.

How does it work ?

Extinguishing via its cooling effect, FK-5-1-12/ FK 5112/ NOVEC 1230 fluid works as a gas, yet it is a liquid at room temperature. Because it is not stored or shipped from the factory in pressurized cylinders, FK-5-1-12/ FK 5112/ NOVEC 1230 fluid is easy to handle and charge. FK-5-1-12/ FK 5112/ NOVEC 1230 fluid systems allow for more efficient use of space, requiring about the same number of cylinders as conventional halocarbon agents.

Note: Industry standards require egress from a protected enclosure prior to system discharge.

The Foam Flooding Systems are similar to Water Mist Fire Suppression System / Clean Agent Systems but use an expanding foam solution mixed with water to extinguish the fire. Foam suppression systems are useful for companies which cannot afford the expensive tank and pump system to operate the sprinklers or for when there is a particularly high risk of high flammable liquid which may need cover. Automatic or manual fire detection can be used to release a foam and water mixture which will expand on release of the agent and give a large fire rating cover without the need for large storage or pump tanks.

Applications

Foam systems protect virtually any hazard where flammable liquids are present. These hazards are common to a multitude of industries including Petrochemical, Chemical, Oil and Gas, Aviation, Marine/Offshore, Manufacturing, Utilities, Military, and Transportation. Applications for a Foam Flooding System include oil and chemical storage cylos or tanks and areas which require sprinklers but without the expense of a tank and pumping system

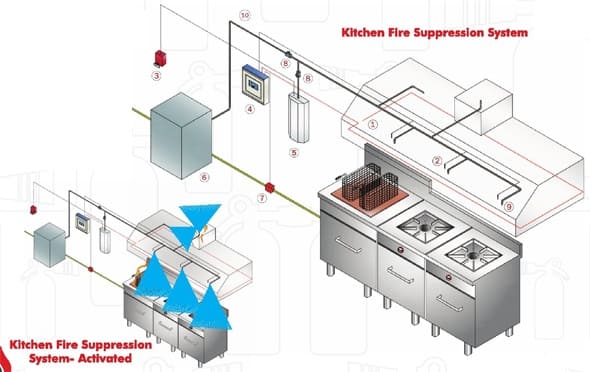

System Design The Kitchen Fire Suppression System / Clean Agent System is designed to provide fire protection in hoods and ducts of cooking appliances for restaurants. The basic system consists of wet agent tank enclosed in a cylinder mounting box, Temperature Sensors, Heat sensing cable, Control panel, Nozzles, piping, & water storage tank (opiional) etc.

The system provides automatic actuation with an option of being actuated manually through a remote manual pull station. The system is also capable of shutting down other appliances on system actuation, if required. Additional equipments such as remote manual pull station, mechanical and electrical gas valves, pressure switches, electrical switches & accessories such as alarms, warning lights, etc. can be integrated with the system. As the fire is detected Control Panel activates the wet agent tank and wet agent is discharged extinguishing the fire. Single and Multi Wei Agent tank system is available. Components of Kitchen Fire Suppression System / Clean Agent System.

| Sr. No. | Description |

|---|---|

| 1 | Heal Sensing Coble |

| 2 | Temperature Sensors |

| 3 | Manual Pull Station |

| 4 | Control Panel |

| 5 | Wet Chemical Agent Storage |

| 6 | Water Storage Tank |

| 7 | Gas Supply Auto Shut Off Valve |

| 8 | Non Return Valve |

| 9 | Discharge Nozzle |

| 10 | Discharge Line |